Description

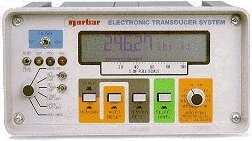

The ETS display, used with one of Norbar’s world leading transducers, provides one of the most accurate measurement systems available. The ETS is not dedicated to a particular transducer, it can be used with as many as are appropriate. Set-up and change over between transducers is very straight forward.

- Full 5 digit resolution.

- All common units of torque are included as well as units of force, pressure, angle and length.

- RS-232-C output as standard.

- Three essential operating modes: track, memory, and ‘memory auto reset’ (for click type torque wrenches).

- Switchable 500 Hz signal filter allows calibration of power tools in accordance with the power tool testing standard, ISO 5393-1994.

The Norbar Power Tool Rundown Fixture simulates joint characteristics by tightening a socket head cap screw through a stack of ‘Belleville’ spring cup washers. This important feature allows power tools to be set or tested for a specific application.

Essential for the accurate setting of pneumatic / electric screwdrivers, angle wrenches and hydraulic pulse wrenches. The rundown fixture screw sets are loaded with spring washers to simulate hard through to soft joint ratings and to comply with ISO 5393-1981 (E).

The rundown fixture must be used in conjunction with the appropriate static torque transducer and ETS display system.

SPECIFICATION:

- Accuracy: ±0.1% of full scale

- Range: 0 – 150% of transducer full scale (unless otherwise specified).

- Resolution: 1’s range transducers, 1 digit in 10,000

- 25’s range transducers, 1 digit in 25,000

- 5’s range transducers, 1 digit in 50,000

ETS Options

| Part Code | Model Description |

| 40320 | ETS |

| 40321 | ETS f/w Internal Battery pack |

| 40322 | ETS f/w Limit Detector |

| 60163 | 5-Way Switch Box |

| 60164 | Data Printer |

| 60166 | ETS Battery Power Unit |

| 60012 | xy/t Chart Recorder |

| 60165 | 10 Channel Selection Unit |

| 40326 | ETS LD for 10 Channel |

Rundown Fixtures

| Part Code | Socket (inches) |

Range | Transducer Required | A/F Size of Hex Screws (mm) |

| 50312 | 1/4 | 0.2 – 2Nm | 50025.ETS | 5 |

| 50130 | 1/4 | 2 – 12Nm | 50026.ETS | 5 |

| 20 – 100lb.in | 50008.ETS | |||

| 50131 | 3/8 | 5 – 70Nm | 50027.ETS | 8 |

| 5 – 50lb.ft | 50005.ETS | |||

| 50132 | 1/2 | 10 – 140Nm | 50028.ETS | 10 |

| 10 – 100lb.ft | 50008.ETS | |||

| 50133 | 3/4 | 100 – 700Nm | 50030.ETS | 19 |

| 100 – 500lb.ft | 50011.ETS | |||

| 51044 | 3/4 | 100 – 700Nm | 50030.ETS | 19 |

| 100 – 500lb.ft | 50011.ETS |

All models include bench stand.

50133 includes a sliding base to allow the transducer and nose assembly to move laterally and remain connected to the tool.

Reviews

There are no reviews yet.