Oil cleanliness play’s a huge role across a wide range of industries around the world every day. From the garbage trucks that collect your rubbish, to the power station that generates your electricity oil cleanliness is vital in ensuring the reliable operation of this equipment. Our team has compiled some information to provide some education around how oil is measured, why oil is measured and what can be done to mitigate and clean dirty oil to ensure down time and costly repairs are minimised wherever possible.

New oil can be one of the worst sources of particulate and water contamination.

25/22/19 is a common ISO code for new oil which is not suitable for hydraulic or lubrication systems. A good target for new oil cleanliness is 16/14/11.

The ISO cleanliness code (per ISO4406-1999) is used to quantify particulate contamination levels per millilitre of fluid at 3 sizes 4m[c], 6m[c] and 14m[c]. The ISO code is expressed in 3 numbers (example: 19/17/14). Each number represents a contaminant level code for the correlating particle size. The code includes all particles of the specified size and larger. It is important to note that each time a code increases the quantity range of particles is doubling and inversely as a code decreases by one the contaminant level is cut in half.

| ISO 4406:1999 Code Chart | ||

|---|---|---|

| Range Code |

Particles per Millilitre | |

| More Than | Up To/Including | |

| 24 | 80000 | 160000 |

| 23 | 40000 | 80000 |

| 22 | 20000 | 40000 |

| 21 | 10000 | 20000 |

| 20 | 5000 | 10000 |

| 19 | 2500 | 5000 |

| 18 | 1300 | 2500 |

| 17 | 640 | 1300 |

| 16 | 320 | 640 |

| 15 | 160 | 320 |

| 14 | 80 | 160 |

| 13 | 40 | 80 |

| 12 | 20 | 40 |

| 11 | 10 | 20 |

| 10 | 5 | 10 |

| 9 | 2.5 | 5 |

| 8 | 1.3 | 2.5 |

| 7 | 0.64 | 1.3 |

| 6 | 0.32 | 0.64 |

| Particle Size | Particles per Millilitre |

ISO 4406 Code Range |

ISO Code |

|---|---|---|---|

| 4μm[c] | 151773 | 80000~16000 | 24 |

| 4.6μm[c] | 87210 | ||

| 6μm[c] | 38363 | 20000~40000 | 22 |

| 10μm[c] | 8229 | ||

| 14μm[c] | 3339 | 2500~5000 | 19 |

| 21μm[c] | 1048 | ||

| 38μm[c] | 112 | ||

| 68μm[c] | 2 |

| Particle Size |

Particles per Millilitre |

ISO 4406 Code Range |

ISO Code |

|---|---|---|---|

| 4μm[c] | 69 | 40~80 | 13 |

| 4.6μm[c] | 35 | ||

| 6μm[c] | 7 | 5~10 | 10 |

| 10μm[c] | 5 | ||

| 14μm[c] | 0.4 | 0.32~0.64 | 6 |

| 21μm[c] | 0.1 | ||

| 38μm[c] | 0.0 | ||

| 68μm[c] | 0.0 |

When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important to keep in mind the objectives to be achieved. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. Once a target ISO cleanliness code is set following a progression of steps to achieve that target, monitor it, and maintain it will yield justifiable rewards for your efforts. Make an impact on reliability by controlling contamination.

The first step in identifying a target ISO code for a system is to identify the most sensitive component on an individual system, or the most sensitive component supplied by a central reservoir. If a central reservoir supplies several systems the overall cleanliness must be maintained, or the most sensitive component must be protected by filtration that cleans the fluid to the target before reaching that component.

Table 1 recommends conservative target ISO cleanliness codes based on several component manufacturers guidelines and extensive field studies for standard industrial operating conditions in systems using petroleum based fluids. If a non-petroleum based fluid is used (i.e. water glycol) the target ISO code should be set one value lower for each size (4μ[c] / 6μ[c] / 14μ[c]). If a combination of the following conditions exists in the system the target ISO code should also be set one value lower:

• Component is critical to safety or overall system reliability.

• Frequent cold start.

• Excessive shock or vibration.

• Other severe operation conditions.

| Pumps | Pressure < 138 bar < 2000 psi |

Media βPx[c] = 1000 (βpx = 200) |

Pressure 138-207 bar 2000 – 3000 psi |

Media βx[c]=1000 (βx = 200) |

Pressure > 207 bar > 3000 psi |

Media βx[c]=1000 (βx = 200) |

|---|---|---|---|---|---|---|

| Fixed Gear | 20/18/15 | 22μ[c] (25μ) | 19/17/15 | 12μ[c] (12μ) | – | – |

| Fixed Piston | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) | 17/15/12 | 7μ[c] (6μ) |

| Fixed Vane | 20/18/15 | 22μ[c] (25μ) | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Variable Piston | 18/16/13 | 7μ[c] (6μ) | 17/15/13 | 7μ[c] (6μ) | 16/14/12 | 5μ[c] (3μ) |

| Variable Vane | 18/16/13 | 7μ[c] (6μ) | 17/15/12 | 5μ[c] (3μ) | – | – |

| Valves | ||||||

|---|---|---|---|---|---|---|

| Cartridge | 18/16/13 | 12μ[c] (12μ) | 17/15/12 | 7μ[c] (6μ) | 17/15/12 | 7μ[c] (6μ) |

| Check Valve | 20/18/15 | 22μ[c] (25μ) | 20/18/15 | 22μ[c] (25μ) | 19/17/14 | 12μ[c] (12μ) |

| Directional (solenoid) |

20/18/15 | 22μ[c] (25μ) | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Flow Control | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Pressure Control (modulating) |

19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) | 17/15/12 | 7μ[c] (6μ) |

| Proportional Cartridge Valve |

17/15/12 | 7μ[c] (6μ) | 17/15/12 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) |

| Proportional Directional |

17/15/12 | 7μ[c] (6μ) | 17/15/12 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) |

| Proportional Flow Control |

17/15/12 | 7μ[c] (6μ) | 17/15/12 | 5μ[c] (3μ) | 16/14/11 | 5μ[c] (3μ) |

| Proportional Pressure Control |

17/15/12 | 7μ[c] (6μ) | 17/15/12 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) |

| Servo Valve | 16/14/11 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) | 15/13/10 | 5μ[c] (3μ) |

| Bearings | ||||||

|---|---|---|---|---|---|---|

| Ball Bearing | 15/13/10 | 5μ[c] (3μ) | – | – | – | – |

| Gearbox (industrial) | 17/15/13 | 12μ[c] (12μ) | – | – | – | – |

| Journal Bearing (high speed) |

17/15/12 | 7μ[c] (6μ) | – | – | – | – |

| Journal Bearing (low speed) |

17/15/12 | 7μ[c] (6μ) | – | – | – | – |

| Roller Bearing | 16/14/11 | 7μ[c] (6μ) | – | – | – | – |

| Actuators | ||||||

|---|---|---|---|---|---|---|

| Cylinders | 17/15/12 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) | 15/13/10 | 5μ[c] (3μ) |

| Vane Motors | 20/18/15 | 22μ[c] (25μ) | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Axial Piston Motors | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) | 17/15/12 | 7μ[c] (6μ) |

| Gear Motors | 20/18/14 | 22μ[c] (25μ) | 19/17/13 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Radial Piston Motors | 20/18/15 | 22μ[c] (25μ) | 19/17/14 | 12μ[c] (12μ) | 18/16/13 | 12μ[c] (12μ) |

| Test Stands, Hydrostatic | ||||||

|---|---|---|---|---|---|---|

| Test Stands | 15/13/10 | 5μ[c] (3μ) | 15/13/10 | 5μ[c] (3μ) | 15/13/10 | 5μ[c] (3μ) |

| Vane Motors | 20/18/15 | 7μ[c] (6μ) | 16/14/11 | 5μ[c] (3μ) | 16/14/11 | 5μ[c] (3μ) |

‘Depending upon system volume and severity of operating conditions a combination of filters with varying degrees of filtration efficiency might be required (I.e. pressure, return, and off-line filters) to achieve and maintain the desired fluid cleanliness.

| Example | ISO Code | ||

|---|---|---|---|

| Operating Pressure | 156 bar, 2200 psi | ||

| Most Sensitive Component | Directional Solenoid | 19/17/14 | Recommended Baseline ISO Code |

| Fluid Type | Water Glycol | 18/16/13 | Adjust Down One Class |

| Operating Conditions | Remote Location, Repair Difficult, High Ingression Rate |

17/15/12 | Adjust Down One Class,Combination of Critical Nature, Severe Conditions |

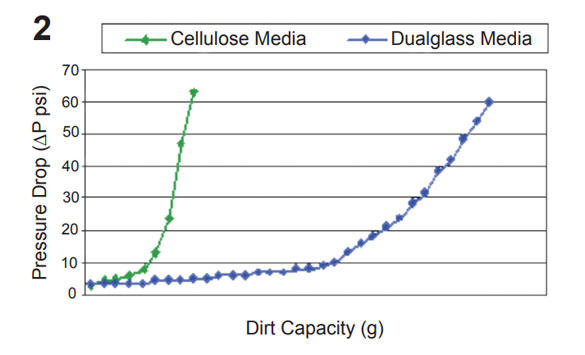

Glass media has superior fluid compatibility versus cellulose with hydraulic fluids, synthetics, solvents, and high water based fluids. Glass media also has a significant filtration efficiency advantage over cellulose, and is classified as “absolute” where cellulose media efficiency is classified as “nominal”.

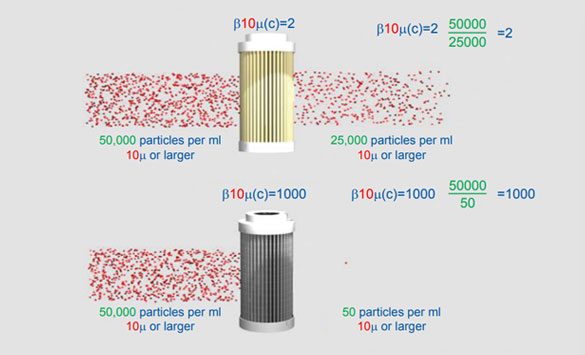

Elements of different media with the same “micron rating” can have substantially different filtration efficiency. Figure 1 provides a visual representation of the difference between absolute and nominal filter efficiency.

The illustrated glass element would typically deliver an ISO Fluid Cleanliness Code of 18/15/8 to 15/13/9 or better depending upon the system conditions and ingression rate. The cellulose element would typically achieve a code no better than 22/20/17.

Runaway contamination levels at 4μ[c] and 6μ[c] are very common when cellulose media is applied where a high population of fine particles exponentially generate more particles in a chain reaction of internally generated contaminate.

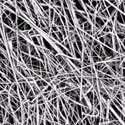

Inorganic glass fibers are much more uniform in diameter and are smaller than cellulose fibers. Organic cellulose fibers can be unpredictable in size and effective useful life. Smaller fiber size means more fibers and more void volume space to capture and retain contaminate.

Glass media has much better dirt holding capacity than cellulose. When upgrading to an absolute efficiency glass media element the system cleanliness must be stabilized. During this clean-up period the glass element halts the runaway contamination as the ISO cleanliness codes are brought into the target cleanliness range. As the glass element removes years of accumulated fine particles the element life might be temporarily short.

Once the system is clean the glass element can last up to 4-5 times longer than the cellulose element that was upgraded as shown in figure 2.

When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important to keep in mind the objectives to be achieved. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. Once a target ISO cleanliness code is set following a progression of steps to achieve that target, monitor it, and maintain it will yield justifiable rewards for your efforts. Make an impact on reliability by controlling contamination.

Waltan Tools and Equipment can help you develop a plan to achieve and maintain target fluid cleanliness. Arm yourself with the support, training, tools and practices to operate more efficiently, maximize uptime and save money.

| Current ISO Code |

Target ISO Code |

Target ISO Code |

Target ISO Code |

Target ISO Code |

|---|---|---|---|---|

| 2 x Life | 3 x Life | 4 x Life | 5 x Life | |

| 28/26/23 | 25/23/21 | 25/22/19 | 23/21/18 | 22/20/17 |

| 27/25/22 | 25/23/19 | 23/21/18 | 22/20/17 | 21/19/16 |

| 26/24/21 | 23/21/18 | 22/20/17 | 21/19/16 | 21/19/15 |

| 25/23/20 | 22/20/17 | 21/19/16 | 20/18/15 | 19/17/14 |

| 25/22/19 | 21/19/16 | 20/18/15 | 19/17/14 | 18/16/13 |

| 23/21/18 | 20/18/15 | 19/17/14 | 18/16/13 | 17/1512 |

| 22/20/17 | 19/17/14 | 18/16/13 | 17/15/12 | 16/14/11 |

| 21/19/16 | 18/16/13 | 17/15/12 | 16/14/11 | 15/13/10 |

| 20/18/15 | 17/15/12 | 16/14/11 | 15/13/10 | 14/12/9 |

| 19/17/14 | 16/14/11 | 15/13/10 | 14/12/9 | 14/12/8 |

| 18/16/13 | 15/13/10 | 14/12/9 | 13/11/8 | – |

| 17/15/12 | 14/12/9 | 13/11/8 | – | – |

| 16/14/11 | 13/11/8 | – | – | – |

| 15/13/10 | 13/11/8 | – | – | – |

| 14/12/9 | 13/11/8 | – | – | – |

Developing a Total System Cleanliness approach to control contamination and care for fluids from arrival to disposal will ultimately result in more reliable plant operation and save money. Several steps to achieve Total Systems Cleanliness include: evaluate and survey all hydraulic and lubrication systems, establish an oil analysis program and schedule, insist on specific fluid cleanliness levels for all new fluids, establish a baseline and target fluid cleanliness for each system, filter all new fluids upon arrival and during transfer, seal all reservoirs and bulk tanks, install high quality particulate and desiccant breathers, enhance air and liquid filtration on existing systems wherever suitable, use portable or permanent off-line filtration to enhance existing filtration, improve bulk oil storage and handling during transfer, remove water and make a commitment to fluid cleanliness.

The visible cost of proper contamination control and total systems cleanliness is less than 3% of the total cost of contamination when not kept under control. Keep your head above the surface and avoid the resource draining costs associated with fluid contamination issues including: