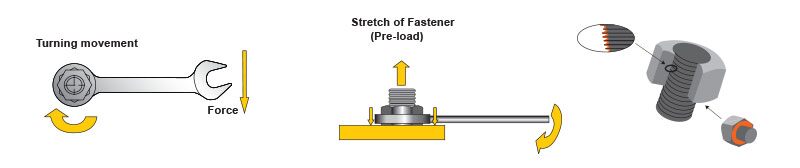

It is a measure of how much force acting on an object which causes that object to rotate.

The application of preload to a fastener by the turning of the fastener’s nut.

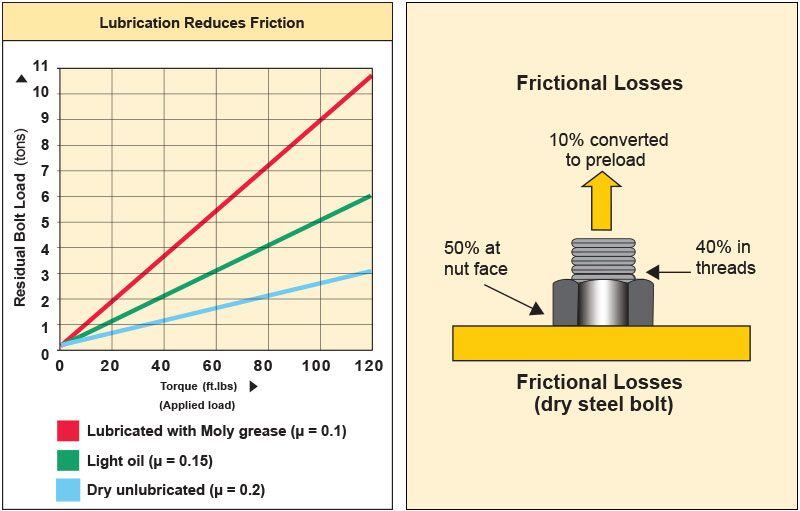

The amount of preload created when torquing is largely dependant on the effects of friction.

Principally there are three different “torque components”:

* Preload (residual load) = Applied Torque minus Frictional Losses *

Friction points should always be lubricated when using the torque tightening method.

Example of how a lubricant can reduce the effect of friction and convert more torque to bolt preload.

Lubrication reduces the friction during tightening, decreases bolt failure during installation and increases bolt service life. Variation in friction coefficients affect the amount of preload achieved at a specified torque. Higher friction results in less conversion of torque to preload. The value for the friction coefficient provided by the lubricant manufacturer must be known to accurately establish the required torque value.

Lubricant or anti-seizure compounds should be applied to both the nut bearing surface and the male threads.

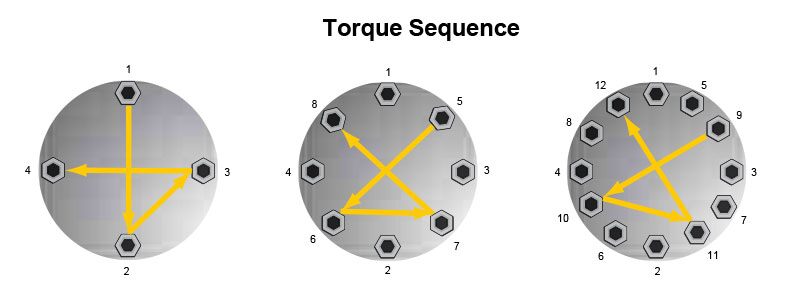

When torquing it is common to tighten only one bolt at a time, this can result in Point Loading and Load Scatter. To avoid this, torque is applied in stages following a prescribed pattern:

Step 1: Spanner tight ensuring that 2-3 threads extend above nut

Step 2: Tighten each bolt to one-third of the final required torque following the pattern as shown above.

Step 3: Increase the torque to two-thirds following the pattern shown above.

Step 4: Increase the torque to full torque following the pattern shown above.

Step 5: Perform one final pass on each bolt working clockwise from bolt 1, at the full final torque.

When loosening bolts a torque value higher than the tightening torque is normally required. This is mainly due to corrosion and deformations in the bolt and nut threads.

Breakout torque cannot be accurately calculated, however, depending on conditions it can take up to 2 1/2 times the input torque to breakout.

The use of penetrating oils or anti-seize products is always recommended when performing breakout operations.