Threaded fasteners are used across industry to assemble products ranging from pipelines to heavy-duty earth movers and from cranes and bridges and many more. Their principle function is to create a clamping force across the joint which is able to sustain the operating conditions without loosening.

Correctly tightened bolts make use of their elastic properties, to work well they must behave like springs. When load is applied, the bolt stretches and tries to return to its original length. This creates compressive force across the joint members.

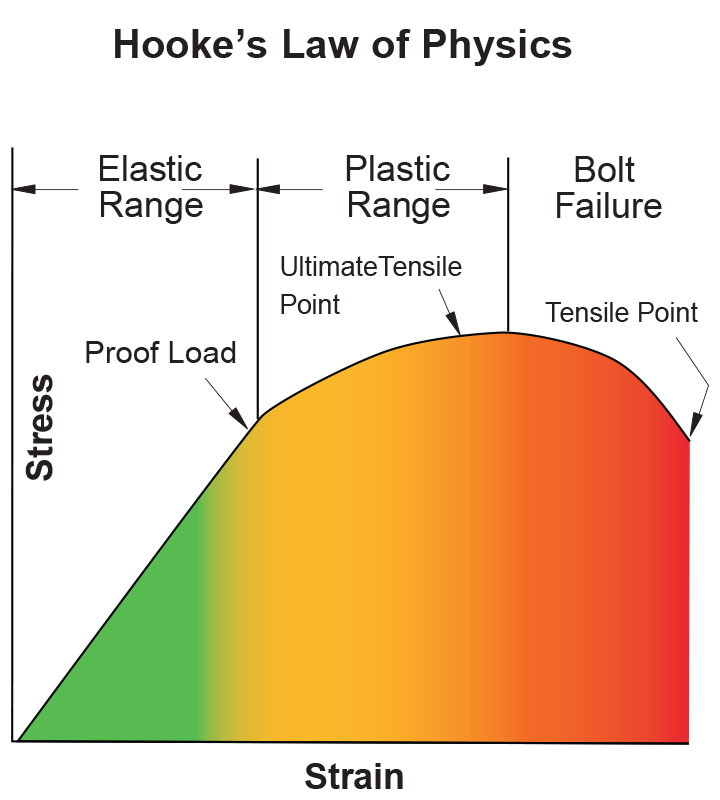

Behavior of Bolts and Nuts Elasticity is defined in Hooke’s Law of Physics: The stress in a bolt is directly proportional to its strain. The stress-strain of a bolt has an elastic range and a plastic range. In this elastic range Hooke’s Law is true.

All of the elongation applied within the elastic range is relieved when the load is removed. The amount of elongation increases when more load is applied. When a bolt is stressed beyond its proof load (maximum load under which a bolt will behave in an elastic manner), the elastic elongation changes to plastic deformation and the strain will no longer be proportional to stress.

In the plastic deformation a part of the elongation will remain after the load is removed. The point where this permanent elongation occurs is called the yield strength. The further application of load takes the bolt to a point where it begins to fail this is termed its ultimate tensile strength (UTS). At this UTS-point, if additional force is applied to the bolt it will continue to elongate until it finally breaks. The point at which the bolt breaks is called the tensile point.

Careful attention must be paid to the grade of bolt being used as bolt grades differ in the elastic range.

Preload

The main purpose of a bolt and nut is to clamp parts together with the correct force to prevent loosening in operation. The term preload refers to the loading in a bolt immediately after it has been tightened.

The amount of preload (residual load) is critical as the joint can fail if the load in the bolt is too high, too low, or not uniform in every bolt.

Uneven bolt loads can result in:

Preload is normally dictated by the joint design, (see Enerpac Bolted Joint Integrity) for information on common joint types or contact your local representative.

Tightening Methods

Principally there are two modes of tightening: “Uncontrolled” and “Controlled”.

Uncontrolled Tightening

Uses equipment and/or procedures that cannot be measured. Preload is applied to a bolt and nut assembly using a hammer and spanner or other types of impact tools.

Controlled Tightening

Employs calibrated and measurable equipment, follows prescribed procedures and is carried out by trained personnel. There are two main techniques: Torque tightening and Bolt Tensioning.

1. Torque Tightening – Achieves preload in a bolt and nut assembly via the nut in a controlled manner using a tool.

2. Bolt Tensioning – Achieves preload in a bolt and nut assembly by stretching the bolt axially using a tool.

Known, controllable and accurate bolt loads

Employs tooling with controllable outputs and adopts calculation to determine the required tool settings.

Uniformity of bolt loading

Especially important on gasketed joints as an even and consistent compression is required for the gasket to be effective.

Safe operation following prescribed procedures

Eliminates the dangerous activities of manual uncontrolled tightening and requires that the operators be skilled and follow procedures.

Reduces operational time resulting in increased productivity

Reduces tightening time and operator fatigue by replacing manual effort with the use of controlled tooling.

Reliable and repeatable results

Using calibrated, tested equipment, following procedures and employing skilled operators achieves known results consistently.

The right results first time

Many of the uncertainties surrounding in-service joint failures are removed by ensuring the correct assembly and tightening of the joint are carried out the first time.